Imagine you’re an engine – not an old BMW iron block, a Mezger, or a Bizzarrini masterpiece, but a generic downsized engine designed to save the world. Picture yourself struggling to squeeze out 200 horsepower from your three cylinders, all while using minimal piston ring tension and running on the thinnest oil available: 0W20. If you’ve ever held 0W20 in your hands, you’ll know – it’s like water. And it’s an absolute disaster for an engine.

Now, imagine starting cold, being thrashed like an ox, without a coolant temperature gauge to warn you. In this scenario, the unburnt fuel droplets from the direct injection mix with the ultra-thin oil on the cylinder walls, creating a deadly cocktail that ignites prematurely, all while the piston is still on its way up. The engine management system is helpless against this violent detonation.

If you’re lucky, low-speed pre-ignition (LSPI) will punch a neat hole through the cylinder in the first few miles. If not, high-rev detonation might finish the job later, as the build-up of carbon deposits causes premature ignition, like a cigarette butt igniting a fuse. Either way, the result is the same: your engine turns into a useless hunk of metal. Rien ne va plus.

It Didn’t Used to Be Like This

Back in the day, a 1.5-liter engine made just 75 horsepower. Sure, it guzzled fuel, and race engines idled at 4,000 RPM, but those days seem almost quaint compared to today’s over-stressed engines. The blend of cost-cutting materials, rushed development, and untested designs has pushed modern engines to their breaking point.

Almost every automaker today has some something to hide these days, and finding a reliable engine is nearly impossible. Broken timing chains, faulty swirl flaps, piston slap, failing oil pumps – you name it. We wouldn’t drive a modern car without a manufacturer’s warranty, not even for an oil change.

The kicker? All these compromises don’t even work. We recently tested two Porsche Panamera 4S models: one with a naturally aspirated 4.8-liter V8 and another with a turbocharged 2.9-liter V6. The older V8 effortlessly cruised at 270 km/h, accompanied by a symphony from the sport exhaust, while the newer V6 strained like a wounded deer, barely more elastic. At the end of our journey, the V8 had consumed just slightly over 12 liters per 100 km, while the V6 drank nearly 15 liters. The problem: despite being more efficient, no one wants the ticking time bomb of the V8 in their garage.

Enter Maserati: The Nettuno

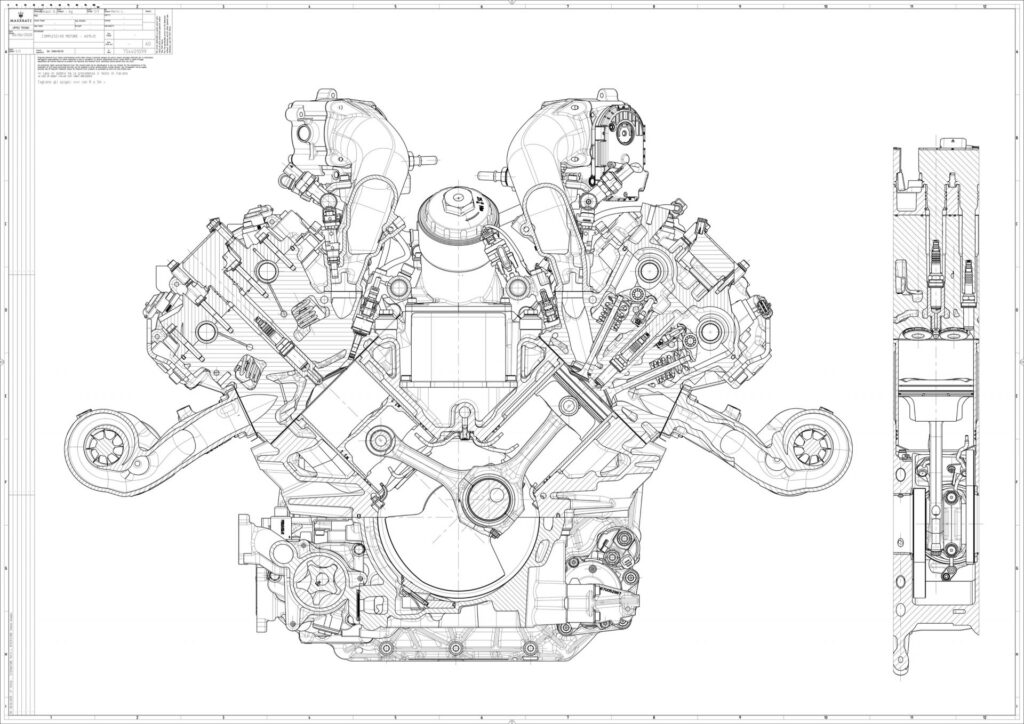

The Nettuno project began in 2015. When pre-chamber cylinder head technology made waves in Formula 1, a small team of developers in Modena saw its potential for Maserati’s road cars. Early design sketches and simulations exceeded expectations, and by the time the first prototype engines were installed in the MC20, it was clear: this would be the engine for Maserati’s next supercar.

But meeting the requirements of emissions regulations, CO2 limits, noise restrictions, and durability was no small task. Failure in any one area could have spelled the end of the MC20 project. To ensure success, Maserati expanded its development team and moved them to a dedicated facility. At the Maserati Engine Hub on Viale Ciro Menotti, they set up a prototype machine shop, modern test benches, and a cutting-edge production line for the new generation of engines. The Nettuno was born – a Formula 1-inspired engine built entirely in Modena.

The Secret

The challenge of balancing high power with low fuel consumption has historically been addressed with downsizing. Smaller displacements, fewer cylinders, and high-precision fuel injection systems paired with turbocharging reduced friction and improved efficiency. But downsizing brought back a problem that was thought to be solved: uncontrolled combustion.

In the past, knocking occurred with poor-quality fuel or from excessive spark advance. Now, the issue is exacerbated by high compression ratios, forced induction, and lean air-fuel mixtures in modern engines. This can lead to what’s known as super-knock – a self-amplifying detonation process that can destroy an engine in seconds.

In today’s engines, the combination of lean mixtures, high cylinder pressures, and thin oils can trigger pre-ignition at low RPMs, especially when cold-start fuel droplets adhere to the cylinder walls. These droplets ignite prematurely, causing catastrophic damage. High-speed pre-ignition is equally dangerous, and there’s no easy fix. The usual solutions – retarding the ignition timing or enriching the fuel mixture – only make things worse. The only option left is to shut off the fuel injection, which sacrifices drivability.

Finally: The Engine That Solves the Problems

Now, let’s talk about the Nettuno, an engine that we certainly didn’t expect to come from Maserati.

At its core, the Nettuno is a classic sports engine – a lightweight, compact V6 with a 90-degree angle between the cylinder banks. The engine block, borrowed from Ferrari (F154), powers models like the California T, Roma, and SF90. It’s a tried-and-tested aluminum block with steel liners, employing a closed-deck design for strength. With a short-stroke configuration (88 mm bore, 82 mm stroke), the Nettuno displaces 3.0 liters and features dry-sump lubrication, dual overhead cams, variable valve timing, and twin turbos.

But the real innovation lies in the cylinder heads. The heart of the Nettuno is its patented twin-spark pre-chamber ignition system. One spark plug sits in a small pre-chamber, separated from the main combustion chamber by carefully designed channels. During the compression stroke, a fuel-air mixture is forced into the pre-chamber, where it ignites. Flame jets then shoot into the main combustion chamber, igniting the remaining lean mixture. This controlled flame propagation ensures even combustion, reducing the risk of knocking and allowing for ultra-lean air-fuel ratios – up to Lambda 2. This results in a 10% reduction in fuel consumption and a 90% reduction in NOx emissions, all while maintaining peak performance.

Performance and Efficiency Redefined

Maserati’s Nettuno isn’t just efficient – it’s powerful. The engine produces 630 horsepower and 730 Nm of torque, with a redline at 8,000 RPM. It also achieves a best-in-class specific fuel consumption of 289 g/kWh. With a secondary spark plug and a combination of direct and port fuel injection, the Nettuno delivers smooth, low-speed drivability while maintaining high performance.

This ambitious development was risky, but it has paid off. The Nettuno will not only power the MC20 supercar but will also be featured in future Maserati models, possibly with hybrid assistance. The MC20 itself is intentionally devoid of hybrid systems – it’s designed to bring Maserati back into motorsport, where performance and weight are paramount.

Maserati’s gamble on the Nettuno has turned out to be a winning one.